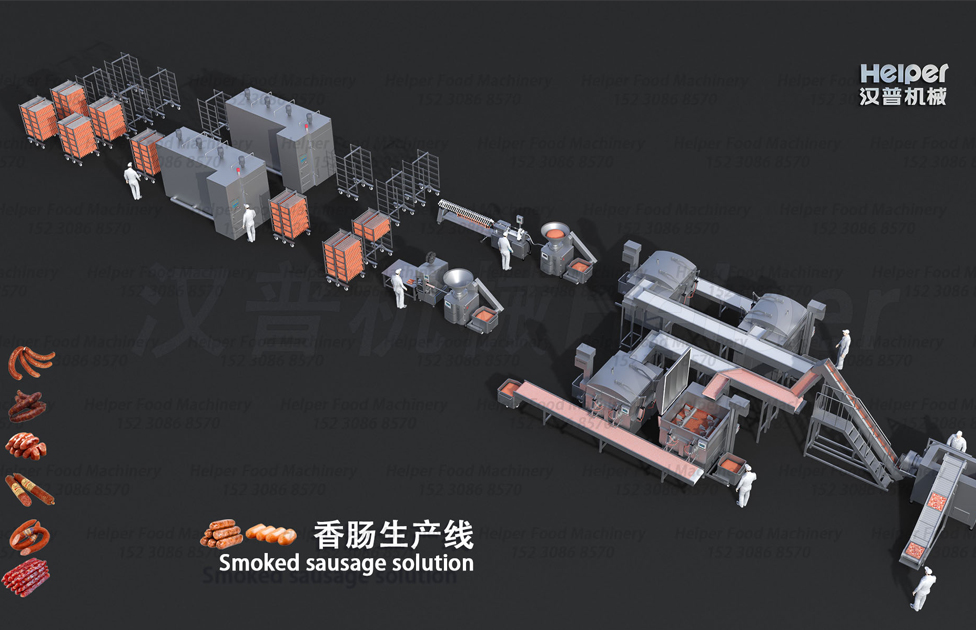

烟熏炉是肉制品熟化过程中必不可少的设备之一,可蒸煮、熏制各种香肠、火腿肠、干肠、腊肠、肉条及羊肉串等,使用本机蒸熏产品,可以确保产品的质量。本机具有蒸煮、干燥、加湿干燥、烘烤、烟熏、发糖上色、排风、清洗等功能。经过十几年的研制生产,根据客户的要求及市场反馈信息,对产品进行了更合理的改进,使其加热速度、烟熏效果都达到理想的效果。主机框架夹层均填充进口耐高温聚氨脂发泡材料一次成型,使保温效果增强,密封性好,节能高效。全自动烟熏炉的触摸屏,可编程控制器及继电器,电磁阀等关键电气元件均采用进口产品。大视窗的人机界面,生动直观地显示设备运行状态,可在运行中随时调整时间、温度、湿度、排风大小等状态参数,操作非常简单。具有优异的发烟及循环系统,可使炉内的烟雾均匀分布,从而使肉制品着色均匀,色泽美观,保证产品具有较高的出品率。

Smoke oven is one of the absolutely necessary equipments in the process of making meat products. This machine has such functions as boiling, drying,roasting, smoking, ventilating and cleaning etc. With the experience of decade development and careful consideration of the clients' requirement and market feedback, the product is given reasonable improvement, which has perfected the heating rate and fume smoking effect. The interlayer of the main machine frame is filled with imported high temperature resistant polyurethane frothing material which is able to guarantee good heat preservation, airtightness, energy saving and high efficiency.

Key electric components of automatic_smoke oven such as touch screen, programmable controller, relay and electromagnetic valve etc are all used imported products. Large human-machine interface visually shows the equipment operation and is easy at any time in the running to adjust the operation parameters such as time, temperature, humidity and ventilation etc. With excellent fuming and circulating system, the smoke in the oven can be evenly distributed to make meat products uniform color and a higher yield rate.